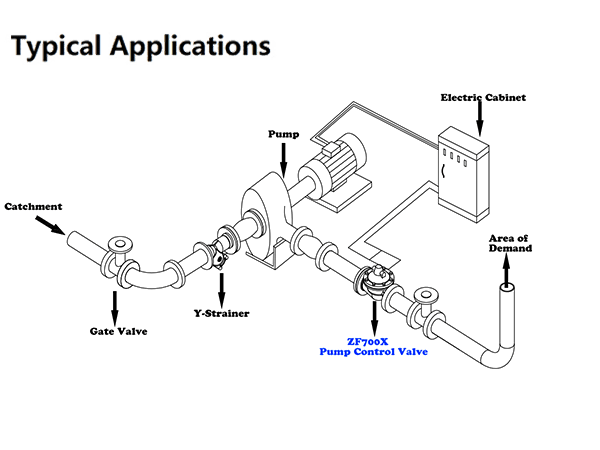

This valve is installed at the outlet of the water pump. It can prevent the backflow of the medium, linked with the water pump, and can effectively prevent the water hammer phenomenon.

Slow closing effectively prevents water hammer.

Stop pump stable and save energy

Full port, small fluid resistance

Completely Automatic Operation

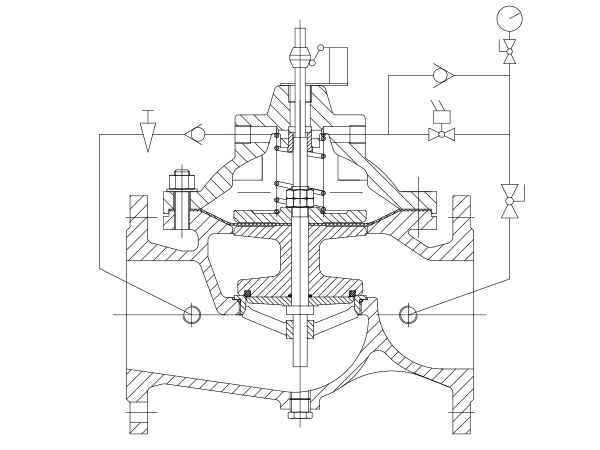

When the pump is started, the solenoid pilot valve is fully opened after electrification, and adjust the needle valve to the appropriate opening degree, upstream water enters the main valve control room through the pipe and flows out through the solenoid pilot valve, at this point, the pressure of the main valve control room keeps the main valve open and at the appropriate opening degree to keep the normal water supply downstream. When the water pump stops working, the solenoid pilot valve closed after power is cut off, the main valve control room stops to drain, the pressure of the control room rise, the main valve begins to close. When close to 90% position, the upper routing switch of the main valve outputs the stop signal and the pump stops running. At this point, the downstream backwater enters the main valve control room through the pilot pipe, the pressure of the control room increases to close the main valve.

The water pump control valve shall be installed at the outlet of the pump and shall be installed on the pipeline of the one-way flow of the medium. It does not need other devices and energy except using solenoid pilot valve control. For specific use, please consult ZECO Valve Group.

Size Range: 2"~24"

Pressure Rating: 10bar ~ 25bar

Face to Face Dimensions: AMSE B16.10, EN558-1

Flange End Dimension: AMSE B16.1/16.42, AS4087, EN1092-2

Coating: Fusion Bonded Epoxy Coating

Inspection and Test: ISO 5208 / EN 12226-2

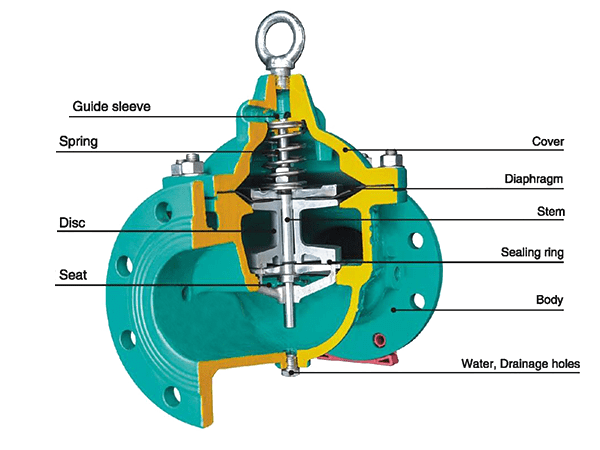

Part | Material | Standard |

Body | Ductile Iron | EN 1563/DIN 1693 |

Ductile Iron | EN 1563/DIN 1693 | |

Trim | Stainless Steel 431 | EN10088-1/ASTM A959 |

Seat | Stainless Steel 431 | EN10088-1/ASTM A959 |

Diaphragm | EPDM / NBR | ISO 4633 |

Pilot Valve | CuZn39Pb1 / C37000 | EN12167/ASTM B135 |

For the materials options not listed, consult factory. ZECO manufactures valves in more than 50 different alloys. | ||