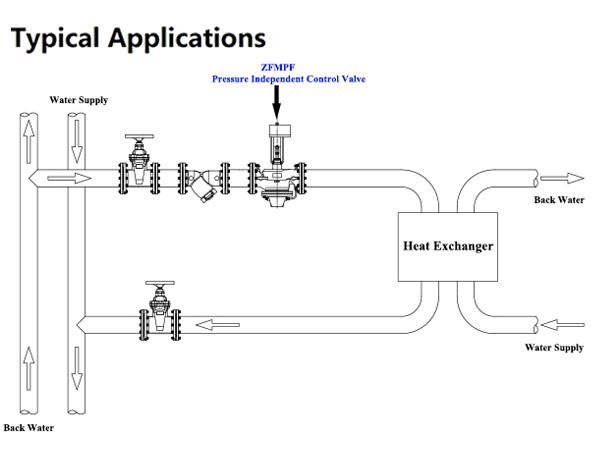

PICV can manually adjust the set flow rate in the pipeline, and also can automatically maintain the pressure difference before and after the valve unchanged, so as to achieve the controlled pipe road flow constant.

Flow regulation and hydraulic balance are integrated;

The self-acting diaphragm differential pressure controller responds quickly to the change of flow rate;

Reduce the use of air conditioning system valves;

Improve the efficiency of water pump operation and save energy.

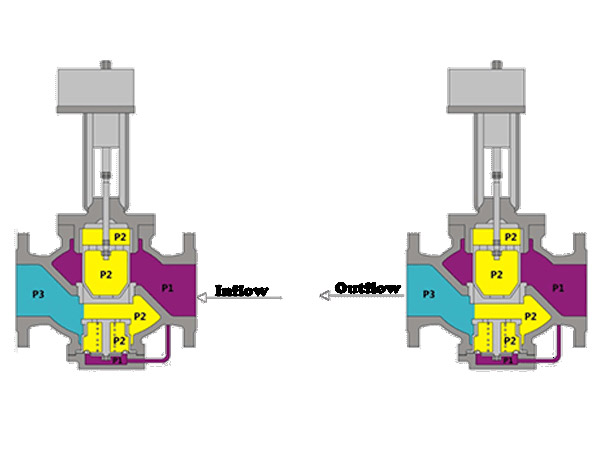

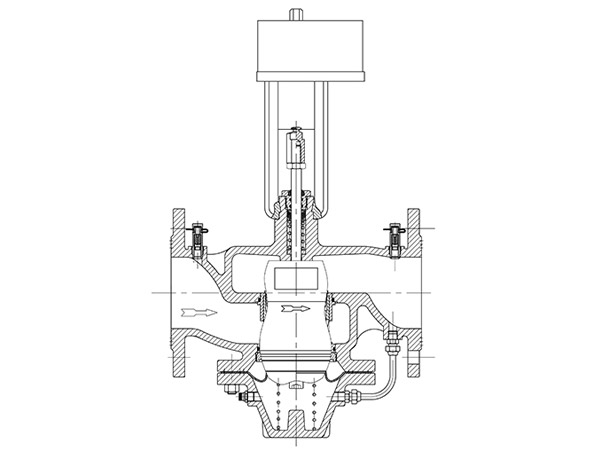

PICV valve keeps ∆P constant through the spring force. The pressure channel inside the valve body will adjust the pressure P1 and P2 at both ends of the structure, causing the upper and lower ends of the diaphragm respectively. The balance state P1=P2+P spring will be maintained through the action of spring force. If P1 increases, the force acting on the lower part of the diaphragm increases correspondingly, and the diaphragm moves upward, reducing the pressure difference control structure space, and P2 increases accordingly to reach a new balance. And vice versa; And PICV valve adjust the flow rate by adjusting the disc to change the Kv value.

Specifications are determined according to the design flow rate of the air conditioning box and allowable pressure range of pressure independent balancing valve, and technical parameters are determined according to the requirements. For specific use, please consult Zeco Valve Group.

Size Range: 2"~12"

Pressure Rating: 10bar ~ 25bar

Face to Face Dimensions: AMSE B16.10, EN558-1

Flange End Dimension: AMSE B16.1/16.42, AS4087, EN1092-2

Coating: Fusion Bonded Epoxy Coating

Inspection and Test: ISO 5208 / EN 12226-2

Part | Material | Standard |

Body | Ductile Iron | EN 1563/DIN 1693 |

Bonnet | Ductile Iron | EN 1563/DIN 1693 |

Trim | Stainless Steel 304 | EN10088-1/ASTM A959 |

Seat | Stainless Steel 304 | EN10088-1/ASTM A959 |

Diaphragm | EPDM / NBR | ISO 4633 |

Electric Actuator | Honeywell | ML7421A-A/B |

For materials options not listed, consult factory. Zeco manufactures valves in more than 50 different alloys. | ||